3D printing in the fixture sector

La 3D printing for the industrial and manufacturing sector has become a key element of the Industrial 4.0 revolution and, thanks to technological innovation, the industrial 3D printers manage to obtain a Return on investment higher than with conventional production techniques.

Design and the rapid prototyping are just two of the main processes that benefit from 3D printing, reducing the time and costs required to produce a viable product.

Case Study Fixtures Sector

How we brought a competitive advantage

thanks to 3D printing fixtures

Our Layerloop has evolved and along with it our partnership programme to start your own industrial 3D production with our fleet of machines. The Layerloop factory programme is the new long-term rental programme for our range of industrial 3D printers. Production modularity is the main aim of this programme. With the layerloop factory programme you lower your running and investment costs without any additional costs. If production increases, you can reconfigure the fee and expand the fleet. With 3D printing we have been able to achieve two competitive advantages compared to competing printers:

-Unlimited print size thanks to the 30° inclined printing axis

-Small industrial 3D printer and customisable to 100% in size, colours and accessory specifications.

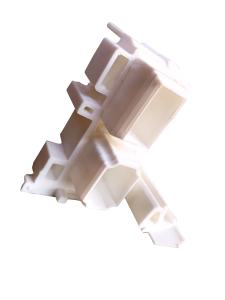

The first issue raised by the company regarding the traditional production of window frames was that of the window frames: I pieces produced were weak due to the moulding production, which did not allow the object to be stiffened in specific parts. Thanks to the industrial 3d printing and to our layerloop we were able to bring an efficient competitive advantage and a reduction in printing costs.

Advantages:

- The window frames are designed with specific stiffeners thanks to special bracing shapes.

- Performance material, elastic and lighter thanks to Nylon.

- Custom build-to-order production can be customised.

- Mass production with reduced support material thanks to the 30° inclined axis.If you would like to keep up to date with the world of 3D printers or would like to request a free consultation for your specific case, click below in the contact form and we will get back to you as soon as possible!

SmartLab 3D Industries together with its subsidiary Finlogic SpA is involved in manufacturing with 3D printers, providing assistance from product selection to after-sales advice and training courses.

LAYERLOOP

was realised by

Smart lab Industrie 3D Finlogic S.p.A

Registered Office:

Bari, Via Calabria 12 - Z.I.

70021 Acquaviva delle fonti (Bari)

Entered in the register of innovative start-ups

Subsidiary of the Finlogic Group SpA

Affiliated Locations: Bari, Teramo, Molfetta, Reggio Calabria

Mail: info@smab3D.it

Tel: 080 8890568

SERVICES

3D Service

___________________

3D Printers

___________________

UV plotter

___________________

3D printer consumables

___________________

Franchising 3D Printers

___________________

INFO

Inside Smart Lab 3D

___________________

Contact

___________________

News

___________________

Case Studies

___________________